so new car , new project m new plans for it , and gathering new info what could be done witt it and choosing what fits me

what i bought

how it looked in my yard next day

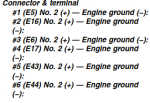

changing inside and some outside bulbs to led's

examples for myself how lift would look with my rims and how bumper cut would look

so normal steps for me do lift at least as much as in that pic, and then maybe cut bumper

car how its sits now, how +5cm would look and then +7cm wheel is in the air

would need bigger tires for better look there.

checked front arches for rust and how it looks, and put some bitumen spray over there , and then put back that plastic cover back

front grill plasti dipped to black

how it looks in dark with some lights

what i bought

how it looked in my yard next day

changing inside and some outside bulbs to led's

examples for myself how lift would look with my rims and how bumper cut would look

so normal steps for me do lift at least as much as in that pic, and then maybe cut bumper

car how its sits now, how +5cm would look and then +7cm wheel is in the air

would need bigger tires for better look there.

checked front arches for rust and how it looks, and put some bitumen spray over there , and then put back that plastic cover back

front grill plasti dipped to black

how it looks in dark with some lights