You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

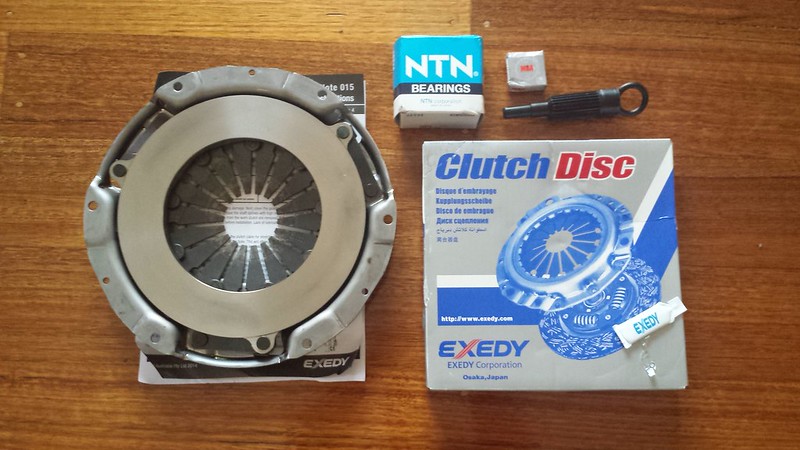

EJ22 Swap into SF Foz Part 1

- Thread starter NachaLuva

- Start date

El_Freddo

Forum Member

- Joined

- Aug 11, 2008

- Messages

- 2,399

- Location

- Bridgewater, Vic

- Car Year

- 1988, 1990

- Car Model

- EJ22'd L series; Targa Brumby

- Transmission

- Locking FT4wd 5spd Manual, 4.111:1 diff w 1.59:1 low range & front OBX LSD ;)

"And-Den?"

Just asking

I hope it's all going well!

Cheers

Bennie

Just asking

I hope it's all going well!

Cheers

Bennie

pezimm

Forum Member

Oh the suspense!

Lol, should have time tomorrow to do the timing belt. I think I'll also remove the sump & give that a clean. A few more bits to collect

Dedman

Forum Member

- Joined

- Dec 3, 2012

- Messages

- 766

- Location

- Perth Western Australia

- Car Year

- 1999

- Car Model

- Forester

- Transmission

- 5MT

Going to be great when its all together

Ill be interested to see what kind of build up in the sump there is on an engine that old.

Ill be interested to see what kind of build up in the sump there is on an engine that old.

Its 23 years old but only 120,000kms, so it will be interesting. There's a LOT of oil on the outside of the engine, I presume from the seals. They didn't do a very good job of steam cleaning it!

pezimm

Forum Member

Lol, should have time tomorrow to do the timing belt. I think I'll also remove the sump & give that a clean. A few more bits to collect

If you're pulling the sump out, you might want to brace/re-inforce your oil pick-up. I recall reading horror stories of people that had that cracked with the smallest bump of the sump.

More here:

https://www.subaruforester.org/vbulletin/f87/ultimate-oil-pickup-install-thread-55376/

I know we all use bash plates, but you never know...

Cheers,

Pedro.

The EJ22 as it was delivered:

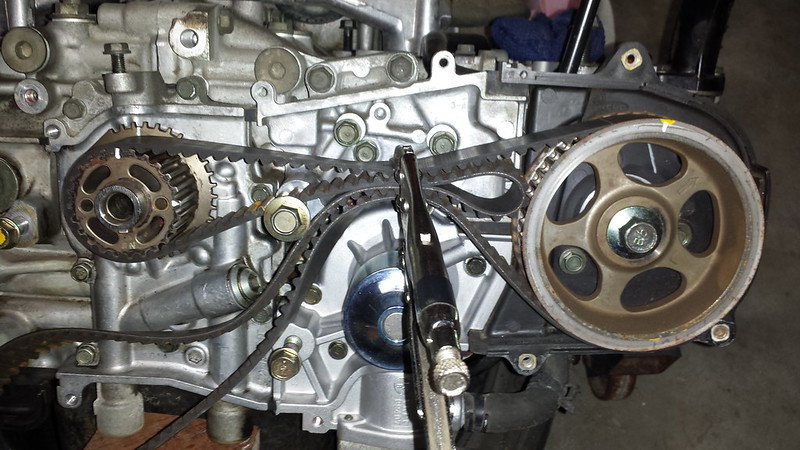

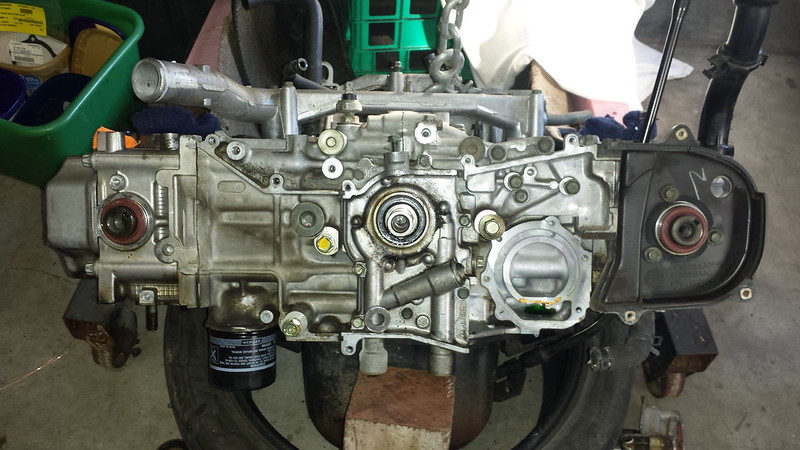

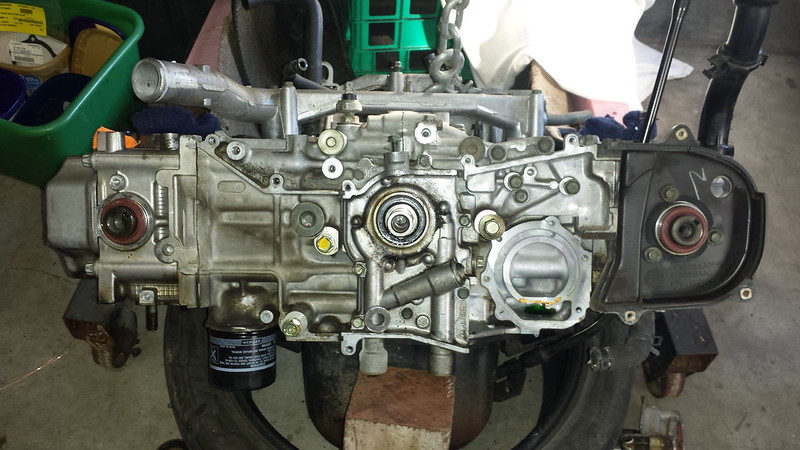

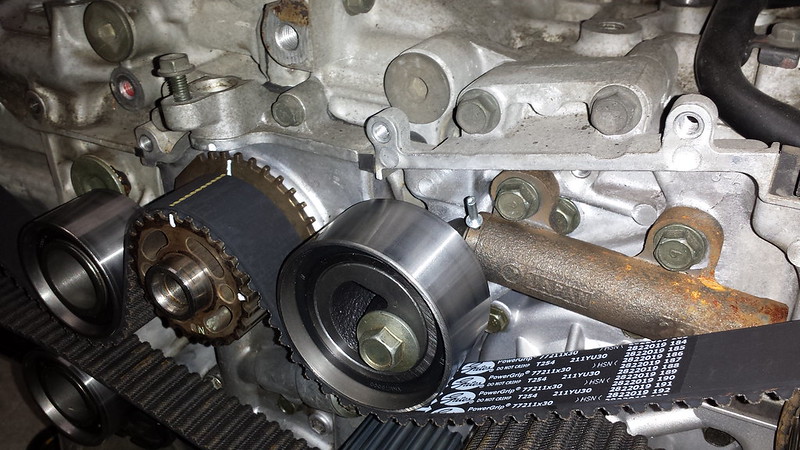

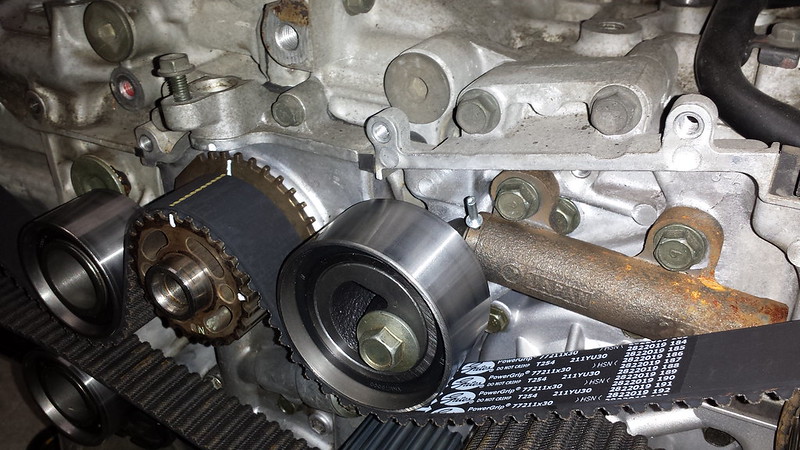

As it sits now:

The crank sprocket was a real bugger to remove. The severe cold we've been getting has probabbly been shrinking it on. I soaked it in Penetrene over several days, but it still wouldnt come off. I bought a gear puller but the fingers wouldn't fit behind it.

So then I tried the WSM method lol. Large screwdriver either side and lever it off, it worked! :biggrin:

Today I'll do the seals & water pump, etc

As it sits now:

The crank sprocket was a real bugger to remove. The severe cold we've been getting has probabbly been shrinking it on. I soaked it in Penetrene over several days, but it still wouldnt come off. I bought a gear puller but the fingers wouldn't fit behind it.

So then I tried the WSM method lol. Large screwdriver either side and lever it off, it worked! :biggrin:

Today I'll do the seals & water pump, etc

Dedman

Forum Member

- Joined

- Dec 3, 2012

- Messages

- 766

- Location

- Perth Western Australia

- Car Year

- 1999

- Car Model

- Forester

- Transmission

- 5MT

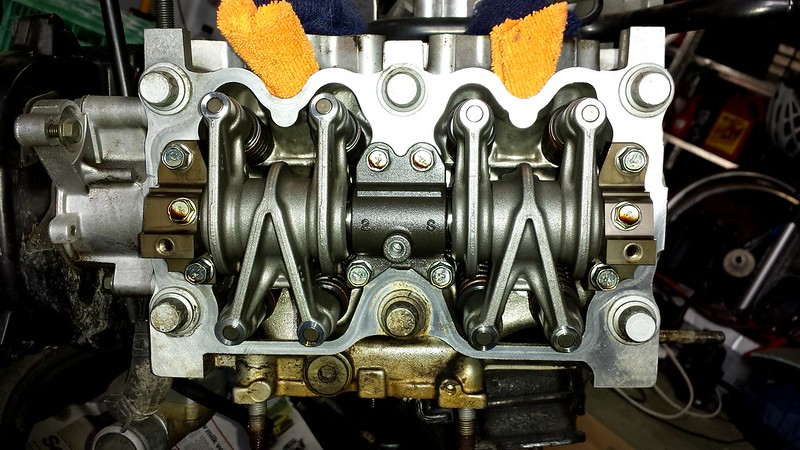

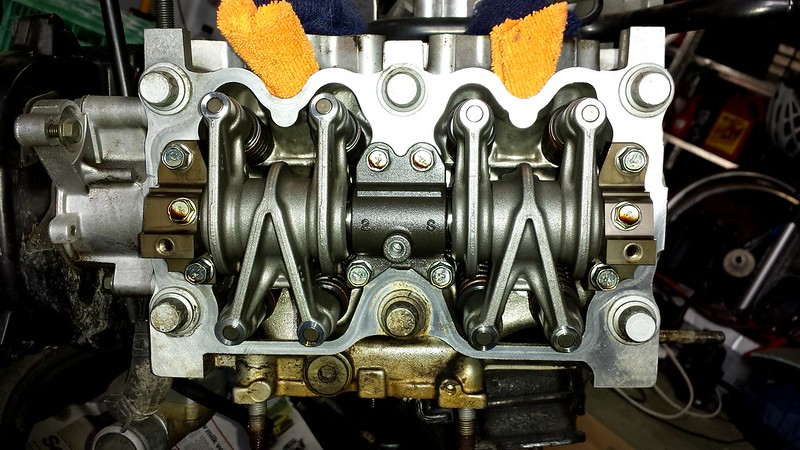

This is how I held the cam sprocket in place while I torqued the bolt. Using the OLD timing belt lol

Thats exactly how I did it. Looks like its coming together nicely. Another day and it will be in? Then the hold your breath moment of turning the key....

Haha, ease up there! I'm not as at home on engines as you lol. Still have to put the belt and pulleys on, double check it's right. Then rocker cover gaskets, oil sump clean & seal, make a bracket to lift it for the front...then I'm ready.

Plus I'm busy doing lift kits inbetween...

Plus I'm busy doing lift kits inbetween...

Dedman

Forum Member

- Joined

- Dec 3, 2012

- Messages

- 766

- Location

- Perth Western Australia

- Car Year

- 1999

- Car Model

- Forester

- Transmission

- 5MT

Yeah probably best to take it slow and get it all correct the first time

Are you removing the sump completely? If so be very very careful not to distort the sump getting it unstuck from the engine. When not perfectly flat I have heard they can be inpossible to reseal.

When I lifted mine I just wrapped straps around the whole thing making sure they were not damaging anything. A bit dodgy but I have a habit of taking shortcuts... All the time.... haha

Are you removing the sump completely? If so be very very careful not to distort the sump getting it unstuck from the engine. When not perfectly flat I have heard they can be inpossible to reseal.

When I lifted mine I just wrapped straps around the whole thing making sure they were not damaging anything. A bit dodgy but I have a habit of taking shortcuts... All the time.... haha

Are you removing the sump completely? If so be very very careful not to distort the sump getting it unstuck from the engine. When not perfectly flat I have heard they can be impossible to reseal.

Any tips how to remove it without damage?

Ratbag

Administrator

- Joined

- Jan 1, 2012

- Messages

- 7,483

- Location

- Bayside, Melbourne, Vic

- Car Year

- MY06, MY10

- Car Model

- Forester SG & SH

- Transmission

- 5MT/DR & 4EAT Sports

^ use a wide (3" or so) paint scraper to break the seal all round (gradually ... ).

If I were to do this sort of stuff again, I would put a thin layer of Silastic on one side of the gasket before fitting ... it's a great product. It would even prevent BMC rocker cover gaskets from leaking oil. Nothing else would ...

If I were to do this sort of stuff again, I would put a thin layer of Silastic on one side of the gasket before fitting ... it's a great product. It would even prevent BMC rocker cover gaskets from leaking oil. Nothing else would ...

El_Freddo

Forum Member

- Joined

- Aug 11, 2008

- Messages

- 2,399

- Location

- Bridgewater, Vic

- Car Year

- 1988, 1990

- Car Model

- EJ22'd L series; Targa Brumby

- Transmission

- Locking FT4wd 5spd Manual, 4.111:1 diff w 1.59:1 low range & front OBX LSD ;)

^ use a wide (3" or so) paint scraper to break the seal all round (gradually ... ).

Totally agree and I'm 99% sure that's how I did mine all those years ago. It's not leaked yet and has taken some hits that it shouldn't have :/

If I were to do this sort of stuff again, I would put a thin layer of Silastic on one side of the gasket before fitting ... it's a great product. It would even prevent BMC rocker cover gaskets from leaking oil. Nothing else would ...

There is no gasket - it's just a silicone (again, from memory!), probably a three bond. All I really remember is that it's grey!

NL, I gutted an old steering extension to use the U part to "hold" one of the arms of the cam gear with the use of a large spanner or screwdriver. No need for a belt, old or new, to do the work and you can torque it up good and proper! Now I have a new piece of kit for the tool box too. Cost me nothing which is even better!

This is also a good trick for the flywheel bolts and the crank bolt - use a little plate with a hole at each end to put on the lower engine mount stud and the flywheel on a clutch bolt. Make sense? I hope so as I thought I had a pic online to use but can't find one, which means that I don't

Cheers

Bennie

What about using RTV sealant for the sump?

I made a tool that bolts onto the flywheel end of the crank to hold/turn the engine, I'll use that to hold it while I torque the crank bolt

I made a tool that bolts onto the flywheel end of the crank to hold/turn the engine, I'll use that to hold it while I torque the crank bolt

Also just noticed there's no timing belt guide...will this matter?

Ratbag

Administrator

- Joined

- Jan 1, 2012

- Messages

- 7,483

- Location

- Bayside, Melbourne, Vic

- Car Year

- MY06, MY10

- Car Model

- Forester SG & SH

- Transmission

- 5MT/DR & 4EAT Sports

^ according to the Haynes manual (IIRC) , this guide is critical for correct installation/clearance.

If you need any gasket paper (oil or water), I have about a metre or so in the garage. IIRC, it's 0.8 mm thick.

If you need any gasket paper (oil or water), I have about a metre or so in the garage. IIRC, it's 0.8 mm thick.

So I took everyone's advice & got a metal oil separation plate:

Tensioner with the pin still in:

As I pull bits off, I like how clean everything is, I think the previous owner was good with oil changes, very little residue:

Almost ready to go in. The sump was a bit rusty so it needed painting anyway, I couldnt resist this high temp paint

:

:

Tensioner with the pin still in:

As I pull bits off, I like how clean everything is, I think the previous owner was good with oil changes, very little residue:

Almost ready to go in. The sump was a bit rusty so it needed painting anyway, I couldnt resist this high temp paint