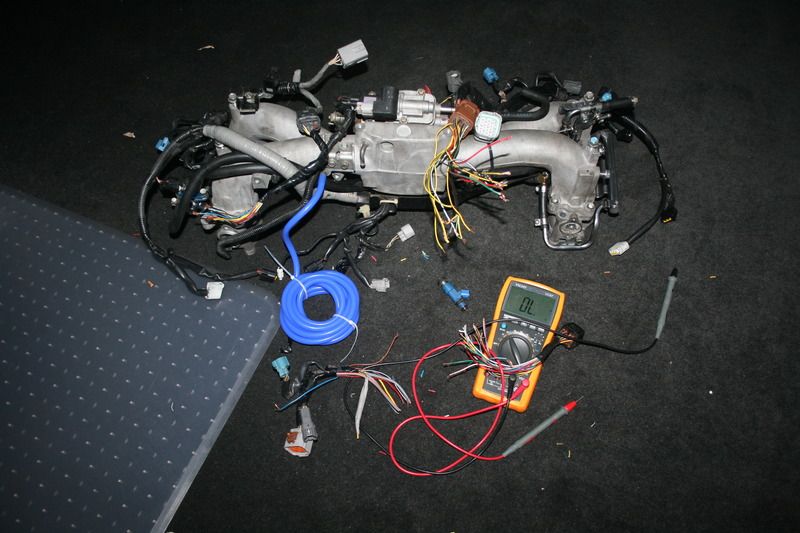

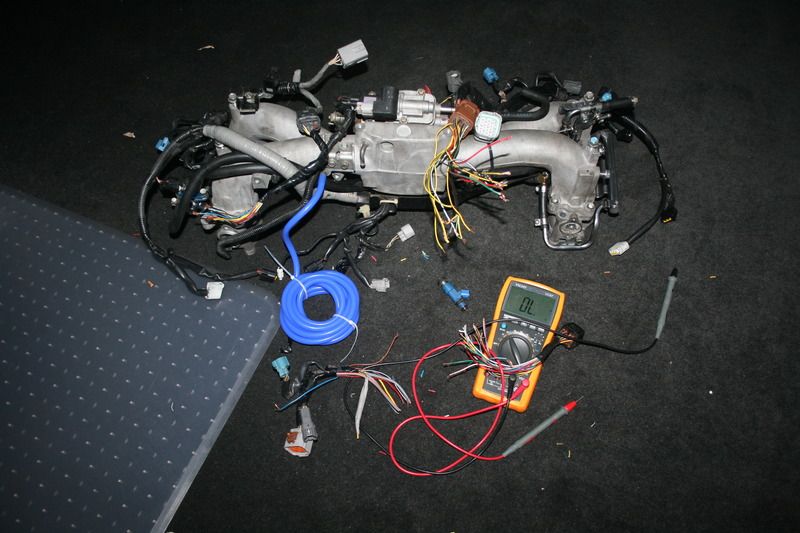

So far, it all been pretty straight forward, but now it would start getting increasingly difficult. One stuff up and I risked blowing my brand new Haltech ECU. First thing was to know what on the engine wiring did what. This required a multimeter and pen and paper, and then what seemed thousands of continuity and later voltage tests. Once I had figured out the engine wiring, I then had the harder task of figuring out the car wiring, deleting what was not going o be used and then adding what was now needed. the old engine ran a single coil pack, whereas this engine ran 4. The old engine only had one cam sensor and no valve control, whereas the new engine ran 2 cam sensors and 2 solenoids to control the cams. The knock sensor on the old engine ran a single wire, the new one 2 wires.

The new engine had 4 connecting points to plug in. I eliminated one and used it for some of the Haltech wiring I would be needed. I used the injector wiring through the firewall, and connected it to the Haltech on one side and to the engine wiring on the other. However, as the standard car only had 2 connectors for the engine near the firewall, I had to run additional wiring from the firewall to the connectors near the fuel filter.

The Haltech is wired totally differently to the Subaru ECU, and for the most part switches to earth. Once I got my head around that, it became much easier. All the while I was still doing continuity testing- multiple times for each wire. Slowly I worked my way through them all. Eventually I had to start looking at providing power. not just to the ECU, but for some of the sensors and all of the solenoids. This would include the idle control solenoid, which, unbeknown to me at the time, was faulty. This would come back to haunt me later.

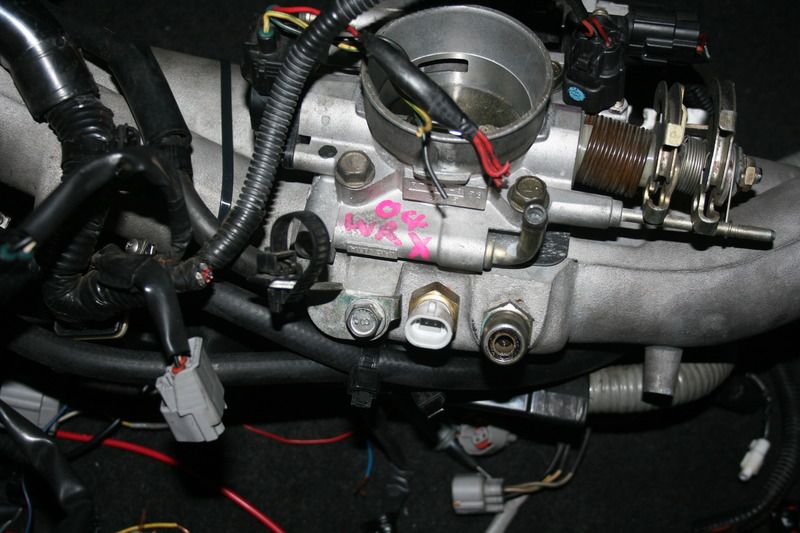

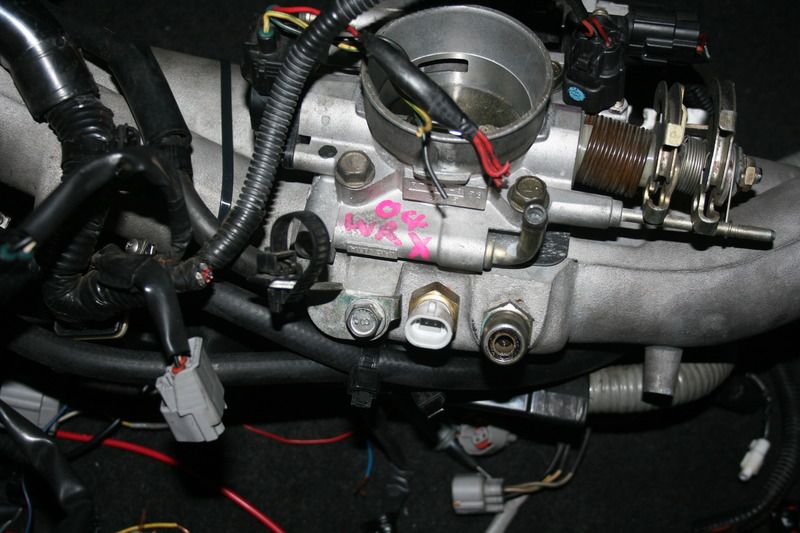

For now, it was a case of removing the inlet manifold in order to allow me to run cable throttle. While the manifold was off, some holes were drilled in it. Once to mount the intake air temperature sensor, the other as a vacuum source for the rising rate fuel pressure regulator. Also while it was off, I upgraded the injectors and split the fuel lines, while at the back of the car, an upgraded fuel pump was installed