Well, I bought it, and I have to say that what SKT has done is truly inspired.

It’s a freaking rocket on the bitumen, and it has an enormous amount of grunt offroad.

Engine transplant thread is here:

https://www.ausubaru.com/forum/showthread.php?t=16564

Here’s a little log of bring it home, and it’s first offroad trip once home.

Jan 29th I flew to Coolangatta. Scott picked me up at the airport and we went for a drive. It didn’t take long for me to be convinced that I should buy this. Sure, it had a couple of issues, for example some worn out bushes in the front end, and a cooling issue, but I could tell that this was a VERY serious vehicle.

Brought it home via Lismore and Casino and then to Tamworth for the night. Next day was Tamworth to Narrandera. Narrandera to Melbourne on the Minday was relatively easy after all of that.

Saw some amazing country in the process. Didn’t have time for many snaps, but here are a few…

Some of the country just into NSW after casino…

Took a detour via the outer solar system…

Actually, that virtual solar system drive from siding spring observatory is a good idea. That pic was taken in Gilgandra.

While on the space bent, couldn’t resist a couple of pics with the Parkes Radio Telescope…

It was 38 degrees Celsius when those shots were taken, and it didn’t get cooler for hours. Unsurprisingly, the vehicle got a bit hot just south of Forbes.

A bit further south past West Wyalong, and there was still water around from December. Ridiculously flat country with paddocks turned to lakes…

So, when I got home, I went straight to the mechanic and got an aircon service. I also consulted about improving airflow to the radiator. I looked at pics of offroad bars on Outbacks on the Subaxtreme site, and also the bar on the latest Forester. Armed with that info I decided to cut some holes in the bulbar, and this is the result…

Gotta love the grille mesh from supacheap auto!

So, I then set up the GPS on the dash with some adhesive Velcro…

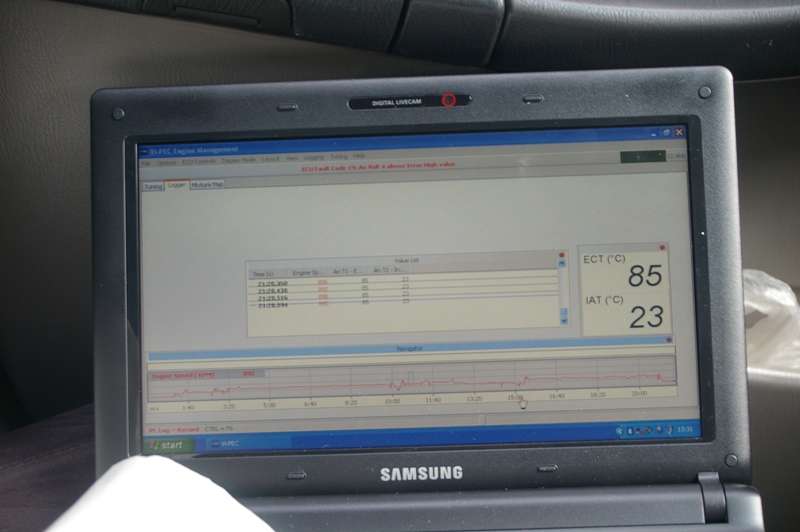

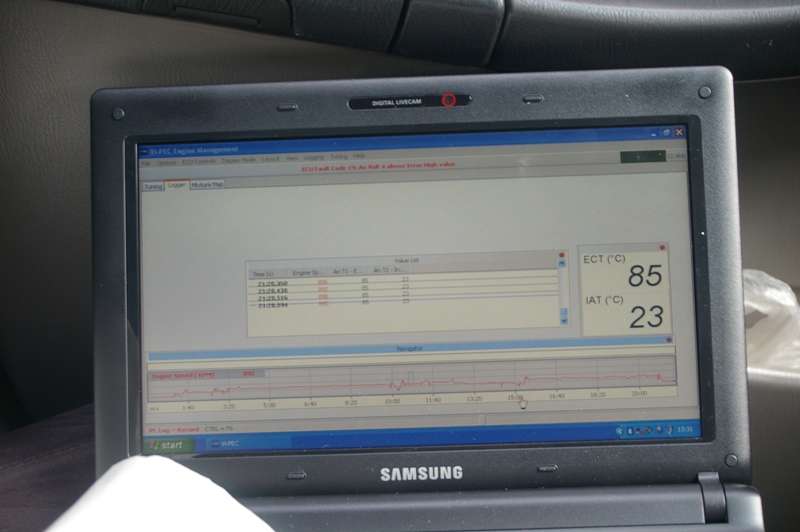

and connected the ECU to the laptop to monitor engine performance and temperatures.

(BTW: I think I might have resolved the “cooling issues”!)

... part two to follow

It’s a freaking rocket on the bitumen, and it has an enormous amount of grunt offroad.

Engine transplant thread is here:

https://www.ausubaru.com/forum/showthread.php?t=16564

Here’s a little log of bring it home, and it’s first offroad trip once home.

Jan 29th I flew to Coolangatta. Scott picked me up at the airport and we went for a drive. It didn’t take long for me to be convinced that I should buy this. Sure, it had a couple of issues, for example some worn out bushes in the front end, and a cooling issue, but I could tell that this was a VERY serious vehicle.

Brought it home via Lismore and Casino and then to Tamworth for the night. Next day was Tamworth to Narrandera. Narrandera to Melbourne on the Minday was relatively easy after all of that.

Saw some amazing country in the process. Didn’t have time for many snaps, but here are a few…

Some of the country just into NSW after casino…

Took a detour via the outer solar system…

Actually, that virtual solar system drive from siding spring observatory is a good idea. That pic was taken in Gilgandra.

While on the space bent, couldn’t resist a couple of pics with the Parkes Radio Telescope…

It was 38 degrees Celsius when those shots were taken, and it didn’t get cooler for hours. Unsurprisingly, the vehicle got a bit hot just south of Forbes.

A bit further south past West Wyalong, and there was still water around from December. Ridiculously flat country with paddocks turned to lakes…

So, when I got home, I went straight to the mechanic and got an aircon service. I also consulted about improving airflow to the radiator. I looked at pics of offroad bars on Outbacks on the Subaxtreme site, and also the bar on the latest Forester. Armed with that info I decided to cut some holes in the bulbar, and this is the result…

Gotta love the grille mesh from supacheap auto!

So, I then set up the GPS on the dash with some adhesive Velcro…

and connected the ECU to the laptop to monitor engine performance and temperatures.

(BTW: I think I might have resolved the “cooling issues”!)

... part two to follow

Last edited:

I really want to see this beast in action one day, but I doubt it will keep up with me, mr turbo or stilson for that matter

I really want to see this beast in action one day, but I doubt it will keep up with me, mr turbo or stilson for that matter