Hey guys,

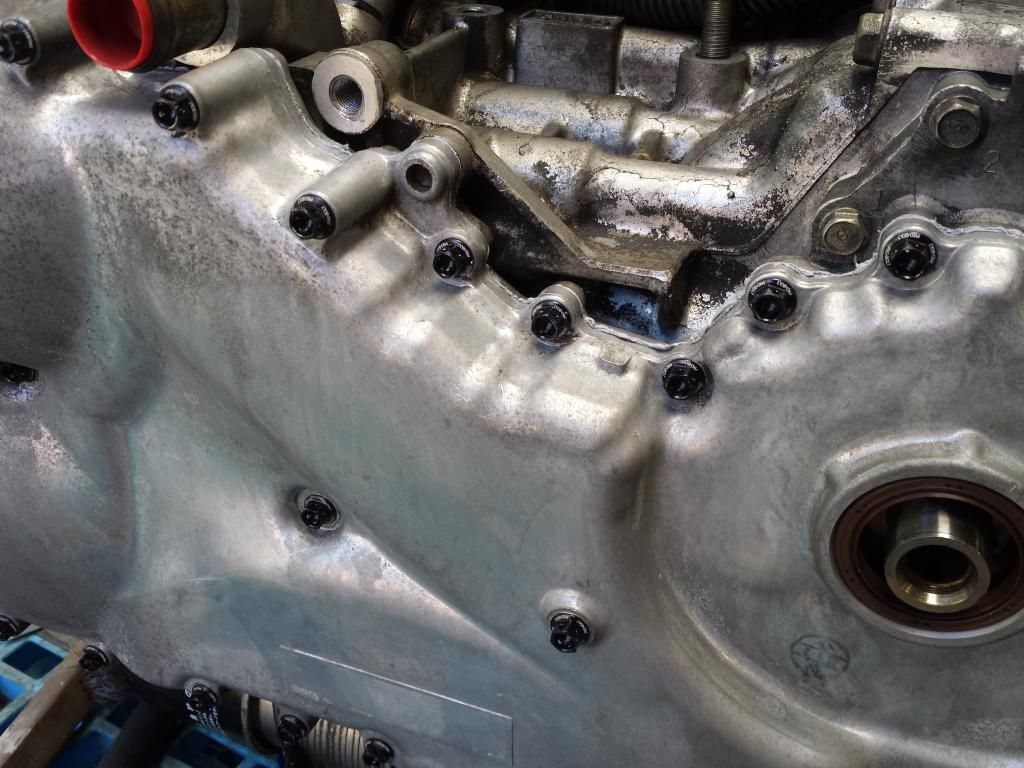

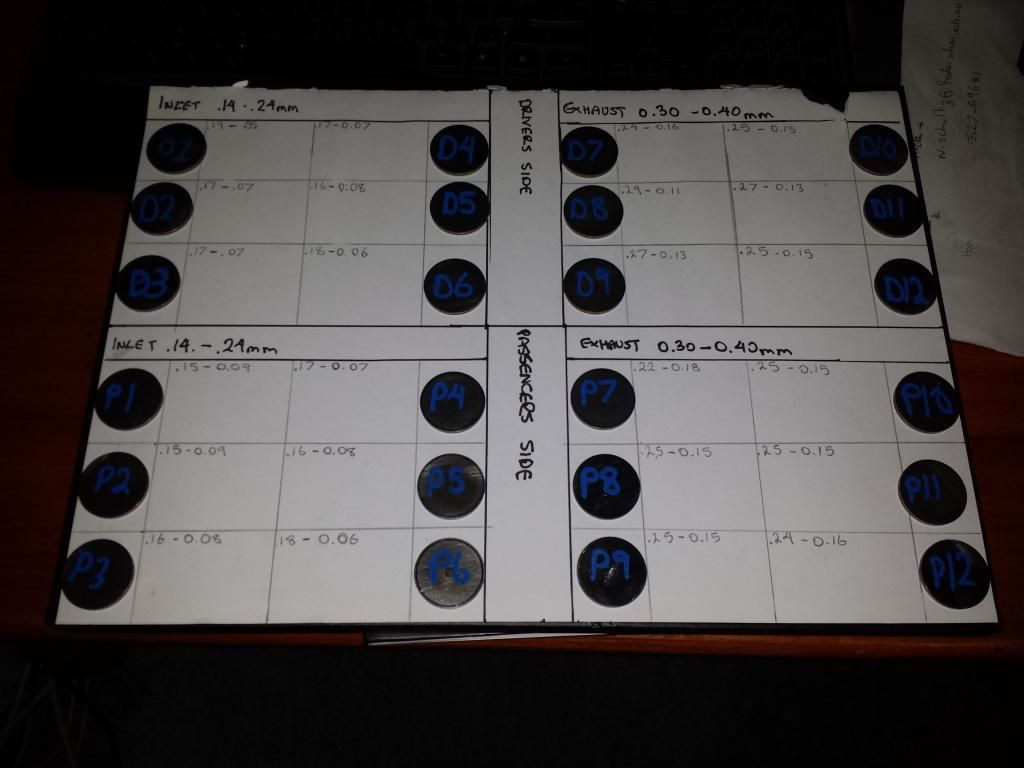

Thought i might share the details of my car around on here I bought this in March. Flew up to Al's from AMAutos place in QLD and drove it back to Victoria with my girlfriend co-driving. This was Als personal car which he converted to a EZ30D. Pit-stop at Bennies to show off on the way back of course. I had a month wait to get into the engineers, which was worth it. Only changes required were a padded steering wheel and a quieter muffler, easy

I bought this in March. Flew up to Al's from AMAutos place in QLD and drove it back to Victoria with my girlfriend co-driving. This was Als personal car which he converted to a EZ30D. Pit-stop at Bennies to show off on the way back of course. I had a month wait to get into the engineers, which was worth it. Only changes required were a padded steering wheel and a quieter muffler, easy  I had to change to stock shocks and springs for the RWC which i wasn't happy about because they were engineered.

I had to change to stock shocks and springs for the RWC which i wasn't happy about because they were engineered.

Current specs are:

2003 Outback H6

V3 STI gearbox

4.44 ratio diffs

Front LSD, clutch pack Rear LSD on my desk

277mm WRX front brakes

Fuel use has so far averaged 9.53L/100km over 5 tanks of fuel. It is very efficient on the highway and around town if driven appropriately.

Plan is to build this into an off-roader.

These are Als pics from the sale and his posts on the conversion process.

Thought i might share the details of my car around on here

Current specs are:

2003 Outback H6

V3 STI gearbox

4.44 ratio diffs

Front LSD, clutch pack Rear LSD on my desk

277mm WRX front brakes

Fuel use has so far averaged 9.53L/100km over 5 tanks of fuel. It is very efficient on the highway and around town if driven appropriately.

Plan is to build this into an off-roader.

These are Als pics from the sale and his posts on the conversion process.

Last edited: