stilson

Forum Member

I stumbled upon a spare rear swaybar (thanks taza) and thought I needed a quick fun project.

My car handles pretty well with the swaybars disconnected now that it has the new shocks and springs but I wanted to reduce the front roll couple.

I lay under the rear or my car for a bit to find the absolute easiest spot to swing a spanner.

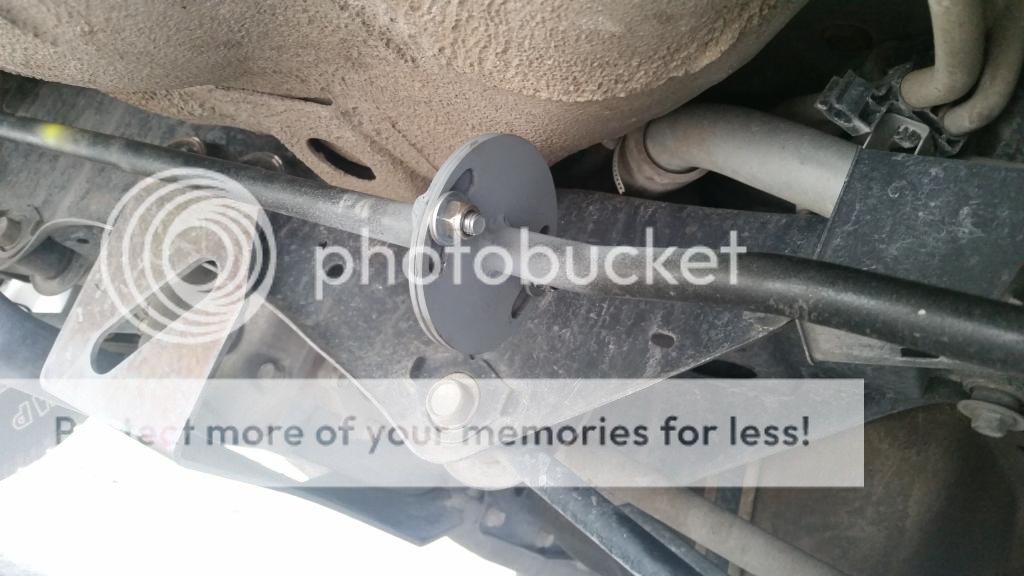

I sectioned 6mm out of the bar. The ID of the hollow bar is 13mm and I had some half inch stainless steel rod. I cut a 100mm piece and welded 40mm of it into one of the pieces of swaybar. I cut 2x 89mm flanges out of 3mm steel plate. I drilled 2x 8.3mm holes in one, then using these as a guide I drilled into the other. I would then rotate the top plate the width of the holes and drill another 10 holes. I cleaned these up with a file to make a smooth track. I then welded the flanges to the 2 pieces of swaybar. I welded 2x 8mm bolts to the first flange and pushed the two swaybar halves together over the stainless rod and bolted the flanges together using a brass then a steel washer on each bolt, and finally a nylock nut.

A quick half turn on each nut and the flanges spin independently of each other.

Seems to work just fine so far but I will have to report back after further (off)road testing.

Last edited:

:biggrin:.

:biggrin:.